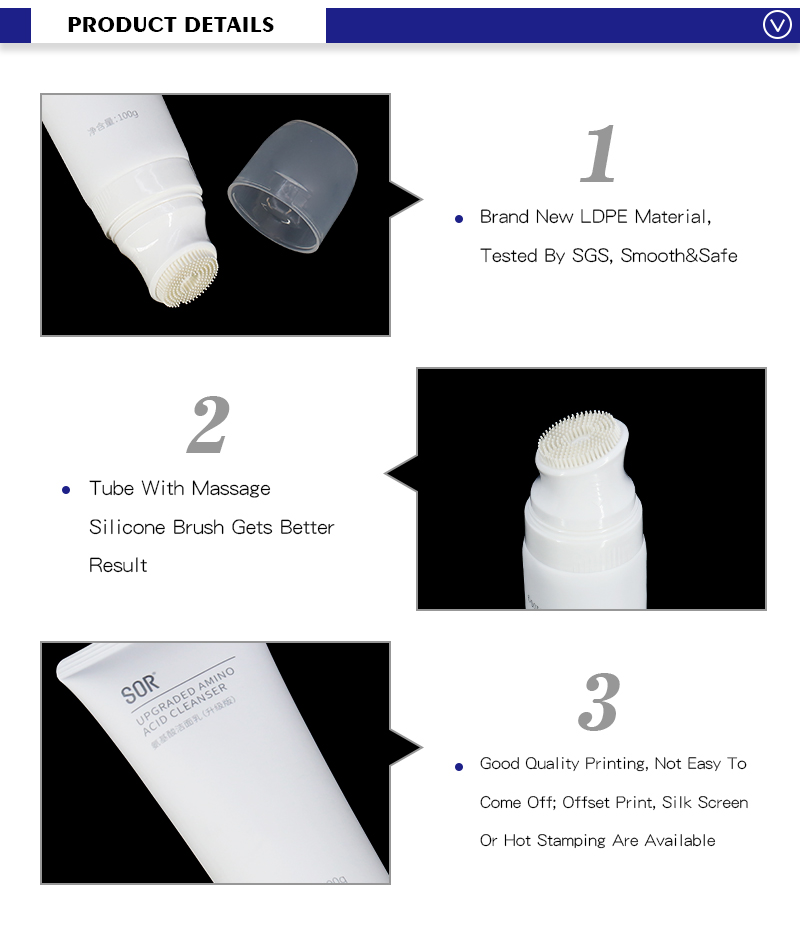

White 100ml Facial Cleanser Plastic Tube With Massage Brush

White plastic cosmetic tube with blank printing , it is with silicone massage brusher .

It is with facial cleaning brusher , which will help do better cleaning.Squeeze out the cream or lotion,then use the brusher to do cleaning . This one is LDPE ,with stablility.

With massage brush , which is soft . You can take to clean your face,neck or others.

Tubes and cap color are available , any color you can ask for the tubes or caps.You can choose which side to seal the mouth or the tail.

Different printing on the surface are also accepted to custom!

|

Capacity

|

100ml/Custom

|

|

Material

|

LDPE

|

|

Color

|

Customized

|

| MOQ |

10000pcs |

|

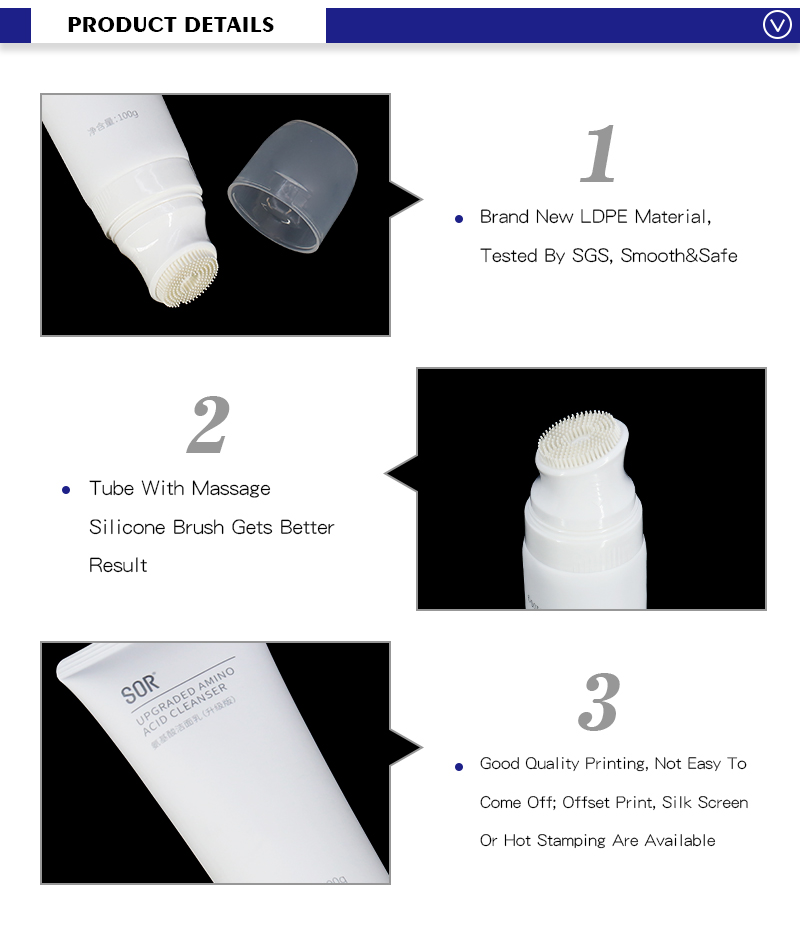

Printing

|

Silk Printing, Hot Stamping, offset printing, labeling ect

|

| Payment Way |

30% Deposite And 70% Balance Before Delivery |

|

Tube size and printing can be customized

|

Integrated Massage Brush Design

This white 100 ml lotion tube includes a built-in silicone massage brush for direct facial application. Users can gently exfoliate and cleanse while dispensing product, improving skincare efficiency and comfort. The flexible brush head is soft and durable, ideal for daily use across wholesale lotion squeeze tubes ranges.

Premium LDPE Material

Manufactured from LDPE, the tube provides strong elasticity and stable structure while remaining lightweight. It resists deformation during squeezing and maintains consistent shape throughout repeated use. This durable build supports Yello’s reputation for dependable plastic tube containers production.

Flexible Customization

Yello supports full customization of tube and cap colors, sealing style, and printing techniques such as silk screen, offset, and hot stamping. Clients may specify matte or glossy finishes, ensuring that each lotion tube aligns with brand aesthetics and functional requirements.

Practical Application Scope

The design suits facial cleansers, gels, creams, and lotions. Its ergonomic brush head also adapts for neck or body skincare use, broadening market compatibility and enhancing consumer experience within the lotion tubes wholesale category.

Product Advantages

Dual-Function Packaging

The integrated silicone massage brush combines application and cleansing, reducing the need for separate tools. This user-focused feature distinguishes the design among wholesale lotion squeeze tubes, improving both convenience and hygiene.

Durable And Safe Composition

LDPE ensures flexibility without leakage or breakage, even under pressure. Each unit undergoes precision molding and quality testing, supporting Yello’s reliability in plastic tube containers for premium cosmetic use.

Tailored Branding Capabilities

Yello’s advanced production allows for detailed printing, custom tones, and finish textures. By personalizing each lotion tube, brands achieve consistent visual identity across product lines, enhancing retail appeal and differentiation.

Massage Silicone brush empty tube Details:

About Us

Founded in 2004, Guangzhou Yello Packaging Co., Ltd. focuses on developing high-quality cosmetic tube solutions for international clients. The company integrates extrusion, printing, sealing, and inspection processes in one facility to ensure quality consistency and cost efficiency. Its portfolio covers LDPE, ABL, PCR, kraft paper, and aluminum tubes designed for skincare, haircare, and personal care applications. Yello’s expertise lies in balancing sustainability, precise craftsmanship, and custom design flexibility—positioning it as a trusted manufacturer in lotion tubes wholesale and plastic tube containers production worldwide.

Request your customized 100 ml lotion tube with massage brush from Yello Packaging today!

FAQ

What is the material of this tube?

It’s made from LDPE plastic for strength, softness, and durability.

Can I customize the tube color and finish?

Yes, Yello offers full color matching and matte or glossy surface options.

Is the brush suitable for facial use?

Absolutely. The soft silicone brush gently massages and cleanses the skin.

What printing options are available?

Silk screen, offset, hot stamping, and labeling are supported.

What is the lead time for production?

Typical production time is 30–35 days following design approval.